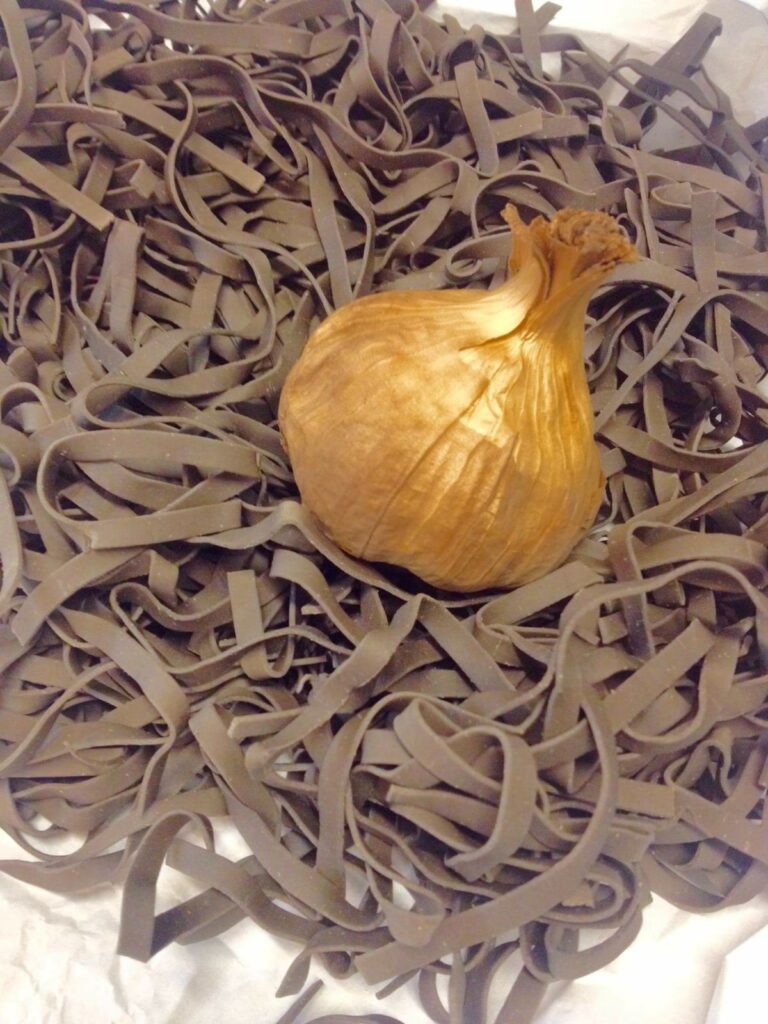

Black Garlic Noodle-how to make at home

Black Garlic Noodle Production Process

Raw Materials & Formulation of black garlic noodle

| Ingredient | Ratio | Specification |

|---|---|---|

| High-gluten flour | 100 parts | Protein content ≥12% |

| Black garlic powder | 3-5 parts | ≥80 mesh, moisture ≤8% |

| Salt | 1-1.5 parts | Food grade |

| Water | 28-32 parts | Purified water, hardness ≤100mg/L |

| Edible alkali | 0.2-0.3 parts | Optional |

Production Process Flow

1. Black Garlic Pretreatment

Steps:

- Select intact black garlic without decay, remove peel

- Slice black garlic into 3-5mm pieces

- Dry at 60°C until moisture ≤8%

- Grind using ultrafine grinder to 80-100 mesh

- Sieving and vacuum packaging for storage

Key Parameters:

- Drying temperature: 60±2°C

- Drying time: 6-8 hours

- Grinding environment: RH ≤45%

2. Ingredient Mixing of black garlic

Steps:

- Weigh ingredients according to formula

- Premix black garlic powder with 30% of flour

- Add remaining flour and other ingredients

- Mix for 15-20 minutes using 3D mixer

Quality Control Points:

- Mixing uniformity CV ≤5%

- Mixing temperature ≤25°C

3. Dough Mixing

Steps:

- Transfer mixed powder to dough mixer

- Slowly add 28-32% purified water (20-25°C)

- Low-speed mixing for 5 minutes, then high-speed for 8-10 minutes

- Endpoint: Dough forms uniform crumbs, holds shape when squeezed but breaks easily

Process Parameters:

- Mixing time: 15-20 minutes

- Dough temperature: 22-26°C

- Final moisture: 30±1%

4. Dough Resting

Steps:

- Transfer dough to resting machine

- Rest for 20-30 minutes

- Slow stirring (5-8rpm) to prevent clumping

Purpose:

- Uniform water distribution

- Complete gluten network formation

- Improve dough processing properties

5. Sheeting & Forming

Steps:

- Compound sheeting: Gradually reduce thickness through 3-5 roller pairs

- Sheet thickness reduced from 4mm to 1mm

- Cut into desired width (1-3mm) with cutting blades

- Adjust blade angle for different noodle shapes

Parameter Control:

- Reduction ratio: ≤50% per pass

- Final sheet thickness: 0.8-1.2mm

- Roller speed: 0.3-0.5m/s

6. Drying

Steps:

- Three-stage drying process:

- Pre-drying: 25-30°C, RH 75-80%, 30 minutes

- Main drying: 35-40°C, RH 55-60%, 2 hours

- Final drying: 25-28°C, RH 45-50%, 1 hour

- Final moisture content: 12-13%

7. Cutting & Packaging of black garlic noodle

Steps:

- Cut to standard length (typically 20-25cm)

- Weighing

- Package with composite film (PA/PE)

- Vacuum or nitrogen-flushed packaging

Packaging Requirements:

- Oxygen transmission rate ≤5cm³/m²·24h·0.1MPa

- Water vapor transmission rate ≤5g/m²·24h

Quality Control Points

| Control Point | Standard | Test Method |

|---|---|---|

| Black garlic powder fineness | ≥80 mesh | Sieving method |

| Mixing uniformity | CV ≤5% | Black garlic content test |

| Dough moisture | 30±1% | Rapid moisture analyzer |

| Final product moisture | 12-13% | GB 5009.3 |

| Breakage rate | ≤5% | Boiling test |

How to Make Black Garlic Noodles at Home